Need an inexpensive and easy way to make your own DIY furniture?

Today, we are going go over how simple it is to make a metal pipe table, which can be a perfect workbench for the garage and even a stunning dining room table (with just a little extra work). The great thing about metal pipe tables is that they are very simple to make. Some people spend thousands of dollars on these tables by buying pre-made ones, when in reality it only costs AT MOST a couple hundred bucks in supplies.

Even less if you how to scrounge for parts like a pro.

We're also going to go over a lot of information on safety tips not normally covered on other sites, so if you plan turn this project into a dinner table, read on for this rustic workbench tutorial!

Supplies:

- (x3) – 30-inch lengths of 2×4 douglas fur* (Support Beams)

- (x3) – 6ft lengths of 2×12 douglas fur (Table Top Boards)

- (x1) – Box of 2 1/2-inch Wood Screws

- (x1) – Belt sander

- (x1) – Basic drill with a bit for your screws and small bit to pre-drill with

- (x1) – Elmer's Carpenter's Wood Filler Max Stainable ( or any quality wood filler that is also stainable)

- (x1) – Quart of wood stain or paint of your choice

- (x1) – Polyurethane scratch resistant sealer

- (x4) – Chip brushes (a cheap throwaway brush available at any hardware or paint store)

- (x1) – Roll of paper towels or throwaway rags

- (x2) – 1-inch black steel pipe threaded tees

- *Douglas fur is the standard framing lumber you find at most supply stores. It is cheap and easy to work with, but you are by no means limited to this type of wood.

Metal Pipes & Hardware (ALL 1-inch diameter)

- (x8) – Threaded iron floor flanges

- (x4) – 24-inch length threaded black steel pipes

- (x2) – 18-length of threaded black steel pipes

- (x4) – 8-inch length threaded black steel pipes

- (x4) – 4-inch length threaded black steel pipes

Step 1: Prepare your supplies

The table we built will be 40-inches high from the floor to the top of the table, 6 feet long, and 34.5 inches wide, but you can obviously change the specs to get your desired height, width, and length. Don't worry if you build one that ends up being too tall or short, as the great thing about pipe tables is it's easy to swap out new sections of pipe for shorter or longer sections to adjust your final product.

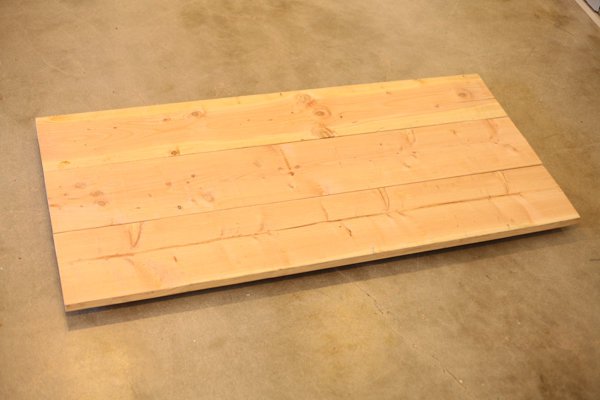

Once you have all your lumber cut to the sizes listed above , you should have a pile of supplies looking like the below images. We are ready to go! Again, feel free to alter your measurements for longer, shorter, or wider tables, etc.

You can also use reclaimed wood for this project if you would like, but please do your research on where your reclaimed wood has been…… You don’t want to use reclaimed wood from a local chemical plant for your new dinning table or you might grow wings or something. Which actually would be pretty cool, but still!

Step 2: Preparing the table top

Once we have all our table top boards cut to size, we lay then down on ground. Like a puzzle, we are going move our boards down till we find the edges (sides) that line up the best without large gaps. Douglas fur is an inexpensive lumber available at almost every lumber supply store out there, but it also tends to have a fair amount of variability in it in term of straightness. Get your three table top pieces lined up nice and even, if you're lucky you won't even need clamps to make all the seams touch.

Note that the side facing down on the floor is the “top” of table surface, while the surface we are looking at is where we will drill and screw on our support beams. So make sure you are looking at the uglier face of the boards when they are on the floor, because that means the prettier side is going to be what you see when the table is all done.

Step 3: Clamping for perfection

We are next going use our large clamps at each side of our arranged table top and clamp the three 2×12 as tight possible to keep the edges together in place while we install the support pieces. This is optional, but big clamps like these are great to have for all manner of woodworking projects, and they will also spare your neighbors from having to help you every time you build something. You can find these 48-inch clamps at any major hardware store and they usually run around $18 a piece.

Step 4: Laying out table top supports

Once our table top is clamped together, we lay out our 3 support pieces across the 3 table top boards (Remember we are still working on what will be the BOTTOM of the table surface). We set our first 30-inch 2×4 along a line 7 inches back from the edge of the table and gave it a 2-inch gap on either side, this way we won't readily see the supports when the table is flipped over.

The center support is placed dead center on the underside of the table, with that same 2-inch gap on the edges of each side. With our 6-foot table, that meant the center beam lay right over the 36-inch (3-foot) mark.

Step 5: Drilling the supports into place

Once the support beams are in place, take your drill with a pilot bit (we used a 1/8th-inch pilot bit, but you can use just about any size so long as it is relatively close to the width of your screws WITHOUT being wider than them) and pre-drill pilot holes for your wood screws into the support beam. We start by holding the support beam in place, then drill and drive a screw in place on each side of the beam ends. This will keep the beam in place as you drill and drive in the other screws to hold the table top surface board to the supports.

We spaced our screws so that each of the 2×12 table top boards received four screws each PER support board. Repeat this until all the beams are secured and so each 2×12 board should have 12 screws all together holding it to the 3 support boards, for a total of 36 wood screws used.

Step 6: Preparing the pipe!

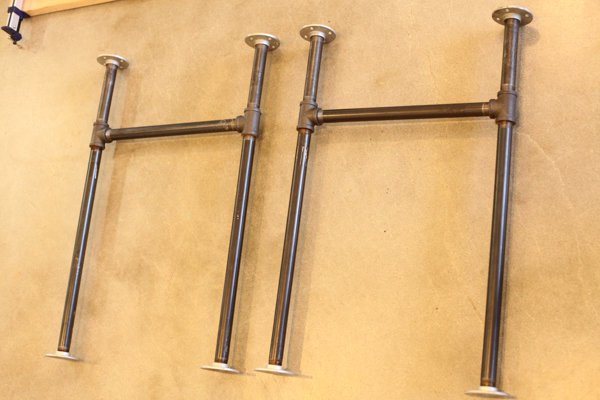

We have “finished” our raw table top. Now we will need to grab our pipes now and assemble the table leg sections before we screw anything onto the table top. You will end up with 2 H-shaped legs.

NOTE ON CHEMICALS: The steel pipe parts can come rather sticky with oil from the factory (the oil is used to cut the metal and protect it against rust). The oils used by companies can vary, but some can contain trace amounts of lead mixed in the oil.

Consequently, if using this table indoors around kids, take the time to clean each pipe thoroughly using steel wool to scrub the pipes all over with a good liquid soap. You can then grab a rag and rub in some of the polyurethane we are going to apply to the table later, which will make the pipes sealed and safe from prying fingers.

In this tutorial, however, we were going more for a fancy workbench version, so there wasn't much use in sealing the pipes, though we did wipe them up with a rag to clean everything so at least our hands wouldn't get too dirty touching the pipes in the future.

Step 7: Creating the bases

Grab all of the 24-inch pipes (4 in total) and screw a floor flange into one side. Don't worry about cranking anything down, just hand-tighten them.

Step 8: T is for Table

Now add your Tee pipe sections onto the 4 legs

Step 9: More support

Now screw your (x2) 18-inch pipe sections into two of the Tee's, which will give you two pipe combinations in the shape of an L.

Step 10: Bringing it together

Now take one of the the other 24-inch pipes which currently has JUST the floor flange and the Tee on it and screw that into the other end of your 18-inch pipe. You will need to spin the full leg to attach the other side to the pipe already attached to the first Tee. You'll end up with two pipe configurations in the shape of a U (or lower case n…or a badly drawn C….you get the idea).

Step 11: Add the adjustable sections

To finish building the leg, grab the 8-inch pipes and thread them into the top of the Tees.

Cap it off by adding your other two floor flanges to the ends, and you have your “H” leg.

Step 12: Repeat

Repeat above steps until you have 2 legs (or more if that's how you like to party). Again, don't over-tighten your bottom leg sections. Just a nice hand tightening will be fine.

Step 13: Attaching the H legs to the underside of the table

Once you have your legs assembled, place them on the support beams so that the LONGER (24-inch) pipes are touching the table.

Center the legs so that the flanges on either side are equidistant from the edge of the 2×4 supports. In this case you should have about 3 inches on either side.

Mark with a pencil were the pipe flange holes meet the wood, or just have someone hold the pipes in place while you drill.

Pre-drill the holes and drive in your 4 wood screws to attach the legs to the wood table top.

Step 14: Repeat for the three remaining flanges.

Once all four flanges are screwed down and secured to the able, go ahead and flip that bad boy over

Step 15: Leveling the table

Now if your table legs are not level (or, in our case, if the floor is really not level) you will need to adjust the legs to keep the table solidly in place. All you have to do is turn the bottom pipe sections until the flanges on every leg sit firmly on the floor.

Step 16: Optional sanding

We are using new lumber that wont need much sanding for our use, but if you're using weathered reclaimed lumber, then you may need to sand…a lot. Most parts of our table are very flat, so we just needed to go around sanding the corners of the boards so they were a little rounded. This was primarily so it would hurt less when we eventually smacked our heads on the edges after dropping a tool.

Sanding can be an all day affair if you're going for baby bottom smoothness, but if you just need to do a cursory treatment to avoid any rough edges, you shouldn't need to spend more than 10 minutes on this table. If you feel any rough burs, go over that part of the wood till you don't. Make sure to also sand away any dirty fingerprint or shoe marks or these will forever be a part your table after you stain it.

If you need/want to do a lot of sanding, get yourself a belt sander with at least a 3×21-inch belt. Make sure you sand ALONG the grain (in the same direction as the lines of the wood run) or you'll get big sanding marks all over. Since our table is nice and flat across already, we just used a small “mouse” sander with a 120-grit sanding disc attached. Even this little dude will make fast work of sharp edges and leave you with a nice smooth finish.

Step 17: Staining

To start staining (or painting if you want to paint it a solid color), we use a damp paper towel over our table top to clean off any saw dust or particles that may interfere with staining. Don't bother buying expensive brushes for staining, just grab some of the $1 chip brushes at the hardware store, throw on some gloves, and have some rags or paper towels handy.

Using chip brushes, we paint on thin coats of stain and go over each area with the rag to clean up any pooling. I like to let the stain sit for 30 seconds or so and then wipe away with a clean paper towel. This lets the wood grain and knots soak up the dark stain, then by wiping it we take stain off areas higher than the knots, leaving you with a lighter wood with dark accents of grain and knots.

Let your stain dry for the recommended time listed on the can being used.

Step 18: Optional filling

Using new wood like we are, the only major area to fill would be the gaps in between each board running down the table. We used a wood filler to help fill in these long gaps. When using reclaimed wood, if you want a very smooth surface you may find yourself sanding and using a lot more filler than we did.

I decided to fill the seams AFTER we stained because I liked the variance in color it gives the table. You may prefer to fill before you stain, which is fine. Just make sure your filler says “stainable” on the front.

OPTIONAL: Stain Touch up

After cleaning up the filler and removing any excess residue, you may still notice some white residue around the edges that look a lil' funky. This is an easy fix and common when using filler. Take your stain and apply a small amount to a rag, then run it over the areas that have the white ashy look. Soon it will disappear, while leaving the filler in the gaps clean of stain.

Step 19: Sealing

After letting the stained wood dry for the recommended time suggested by the stain manufacturer. we take our can of polyurethane sealer and do several coats, building up a thick coat to protect the wood. After all, this is going to be a work bench, so we know its going take a beating.

Sealing is easy and you can just use additional chip brushes for this purpose (good thing these brushes are so cheap!). Lather the wood up with a milky white coat of your poly, brushing it on heavy, and wait about 30 minutes. It will be relatively clear but still tacky by that time, so you can go ahead and hit it again with another coat. Three-to-four coats will be enough for normal use, but seven or eight might be needed if you really plan on beating this thing up.

If making this table for a dinning table surface, you will want to make sure the poly sealer you use is safe, or use a food grade “bar top epoxy” like they do in many bars & restaurants. Just go to a real paint store (not a big box) and ask, they will show you which eco products to use.

Let the clear coat dry for AT LEAST 24hours (longer dry time in cold temps) before placing anything on top of the table. Even if it seems fully dry to the touch, items over the course of only a few hours will become stuck somethin' fierce to your finish. I learned that the hard way when making my first table!

Step 20: Enjoy!

And there's your gorgeous table, perfect for a man cave, kids room to study on, craft table, gardener's potting table, a sultry dining room pub table, or just about anywhere else. The only limits are your imagination! And also square footage.

When referring to the wood or the tree, use the spelling FIR. Fur is the hair on an animal.